Toraidhean

Bolts Steel Steel Hex Head

Tuairisgeul toraidh

| Ainm toraidh | 304 Boldes Steel Steel Hex |

| Stuth | Air a dhèanamh bho 304 stàilinn gun stainsigeadh, tha strì-aghaidh ceimigeach aig na sgriogannan sin agus faodaidh iad a bhith trom le magnetic. Canar iad cuideachd mar stàilinn stain gun staoin. |

| Seòrsa ceann | Ceann Hex. |

| Fad | Air a thomhas bho bhith fon cheann. |

| Seòrsa snàithlean | Snàithlean garbh, snàithlean math. Is e snàithleanan garbh an ìre gnìomhachais; Tagh na sgriothan seo mura h-eil thu eòlach air a 'phàirce no na snàithleanan gach òirleach. Tha snàithleanan grinn agus a-muigh air an còmhdach gu dlùth gus casg a chuir air call a bhonn; Am fraine an snàithlean, is ann as motha a tha an seasamh as fheàrr. |

| Àbhaisteach | Sgriothan a choinnicheas asme b18.2.1 no roimhe seo d din seataichean gèilleadh ris na h-inbhean toicheadh sin. |

Iarrtas

Bidh Bolts Hex stàilinn gun staoin a 'faighinn tagraidhean farsaing thar grunn ghnìomhachasan mar thoradh air an aghaidh, neart agus seasmhachd. Tha an ceann siasagal a 'ceadachadh a' teannachadh furasta le sreang no socaid. Seo cuid de thagraidhean coitcheann airson boltaichean hex stàilinn gun stàilinn:

Tagraidhean Mara:

Tha Bolts Hex stàilinn gun stàilinn an aghaidh a bhith a 'crìonadh, gan dèanamh freagarrach airson an cleachdadh ann an àrainneachdan mara airson obair togail bhàtaichean.

Roinn ola is gas:

Tha boltaichean Hex air an cleachdadh ann a bhith a 'togail agus a' cumail suas feannagan, pìoban, agus bun-structar eile ann an gnìomhachas na h-ola is a 'ghas.

Inneal àiteachais:

Air a chleachdadh ann a bhith a 'cleachdadh uidheamachd àiteachais agus innealan, leithid tractaran agus crann.

Pròiseactan Cumhachd Ath-nuadhachail:

Bithear a 'cleachdadh boltaichean Hesa ann an togail roth-uidheaman gaoithe, structaran pannal grèine, agus bun-structar lùth ath-nuadhachail eile.

Goireasan làimhseachaidh uisge:

Tha boltaichean Hesa ag obair ann an co-chruinneachadh agus cumail suas lusan làimhseachaidh uisge, a 'dèanamh cinnteach à ceanglaichean tèarainte ann an diofar uidheamachd agus structaran.

Giullachd bìdh is deoch:

Tha boltaichean caolta stàilinn gun staoin freagarrach airson a 'ghnìomhachas bìdh is sùlaireachd aca air an aghaidh crìonaidh aca, a chaidh a chleachdadh anns a' cho-chruinneachadh de uidheamachd giullachd.

HVAC (teasachadh, fionnarachadh, agus fionnarachadh-adhartais):

Air a chleachdadh ann an stàladh agus cumail suas siostaman HVAC airson pàirtean agus structaran fhaighinn.

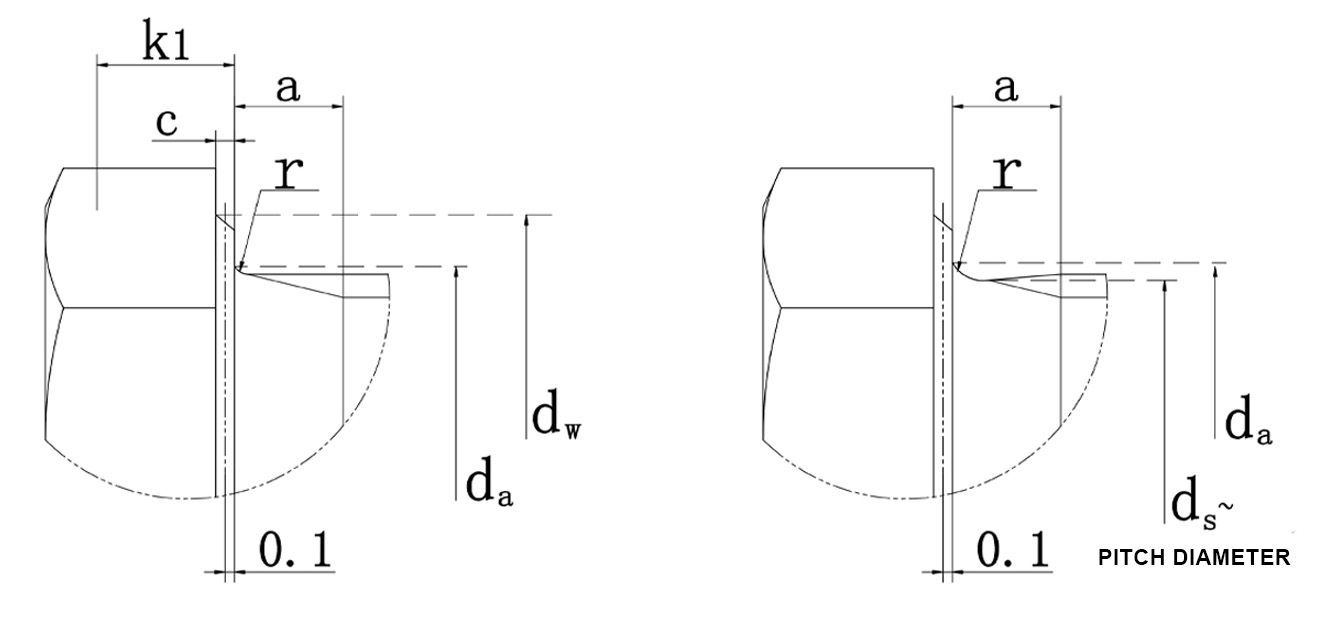

Bolts Hex Steel gun stàilinn din 933

| Snàithlean sgriubha | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | ||||

| d | ||||||||||||||||||

| P | Pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | |||

| a | Max | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 3.75 | 4.5 | 5.25 | 6 | 6 | |||

| c | Mion | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.2 | |||

| Max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | ||||

| da | Max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | |||

| dw | Ìre a | Mion | 2.4 | 3.2 | 4.1 | 4.6 | 5.1 | 5.9 | 6.9 | 8.9 | 9.6 | 11.6 | 15.6 | 17.4 | 20.5 | 22.5 | ||

| Ìre B. | Mion | - | - | - | - | - | 5.7 | 6.7 | 8.7 | 9.4 | 11.4 | 15.4 | 17.2 | 20.1 | 22 | |||

| e | Ìre a | Mion | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 18.9 | 21.1 | 24.49 | 26.75 | ||

| Ìre B. | Mion | - | - | - | - | - | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 18.72 | 20.88 | 23.91 | 26.17 | |||

| k | Meud ainm isminal | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | 8.8 | 10 | |||

| Ìre a | Mion | 0.98 | 1.28 | 1.58 | 1.88 | 2.28 | 2.68 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | 8.62 | 9.82 | |||

| Max | 1.22 | 1.52 | 1.82 | 2.12 | 2.52 | 2.92 | 3.65 | 4.15 | 4.95 | 5.45 | 6.56 | 7.68 | 8.98 | 10.18 | ||||

| Ìre B. | Mion | - | - | - | - | - | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | 8.51 | 9.71 | |||

| Max | - | - | - | - | - | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | 9.09 | 10.29 | ||||

| k1 | Mion | 0.7 | 0.9 | 1.1 | 1.3 | 1.6 | 1.9 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | 5.96 | 6.8 | |||

| r | Mion | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |||

| s | max = meud ainm isminal | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | |||

| Ìre a | Mion | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 16.73 | 18.67 | 21.67 | 23.67 | |||

| Ìre B. | Mion | - | - | - | - | - | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 16.57 | 18.48 | 21.16 | 23.16 | |||

| Snàithlean sgriubha | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | ||||

| d | |||||||||||||||||

| P | Pitch | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | |||

| a | Max | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | 13.5 | 15 | 15 | |||

| c | Mion | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | |||

| Max | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | ||||

| da | Max | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | 48.6 | 52.6 | 56.6 | |||

| dw | Ìre a | Mion | 25.3 | 28.2 | 30 | 33.6 | - | - | - | - | - | - | - | - | - | ||

| Ìre B. | Mion | 24.8 | 27.7 | 29.5 | 33.2 | 38 | 42.7 | 46.5 | 51.1 | 55.9 | 59.9 | 64.7 | 69.4 | 74.2 | |||

| e | Ìre a | Mion | 30.14 | 33.53 | 35.72 | 39.98 | - | - | - | - | - | - | - | - | - | ||

| Ìre B. | Mion | 29.56 | 32.95 | 35.03 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 | |||

| k | Meud ainm isminal | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | 28 | 30 | 33 | |||

| Ìre a | Mion | 11.28 | 12.28 | 13.78 | 14.78 | - | - | - | - | - | - | - | - | - | |||

| Max | 11.72 | 12.72 | 14.22 | 15.22 | - | - | - | - | - | - | - | - | - | ||||

| Ìre B. | Mion | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | 27.58 | 29.58 | 32.5 | |||

| Max | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | 28.42 | 30.42 | 33.5 | ||||

| k1 | Mion | 7.8 | 8.5 | 9.6 | 10.3 | 11.7 | 12.8 | 14.4 | 15.5 | 17.2 | 17.9 | 19.3 | 20.9 | 22.8 | |||

| r | Mion | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | 1.2 | 1.6 | 1.6 | |||

| s | max = meud ainm isminal | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | |||

| Ìre a | Mion | 26.67 | 29.67 | 31.61 | 35.38 | - | - | - | - | - | - | - | - | - | |||

| Ìre B. | Mion | 26.15 | 29.16 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |||

Ansi / asme b1.2.1

| Snàithlean sgriubha | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1-1 / 8 | 1-1 / 4 | 1-3 / 8 | 1-1 / 2 | |

| d | ||||||||||||||

| PP | Unc | 20 | 18 | 16 | 14 | 13 | 11 | 10 | 9 | 8 | 7 | 7 | 6 | 6 |

| Unf | 28 | 24 | 24 | 20 | 20 | 18 | 16 | 14 | 12 | 12 | 12 | 12 | 12 | |

| 8-un | - | - | - | - | - | - | - | - | - | 8 | 8 | 8 | 8 | |

| ds | Max | 0.26 | 0.324 | 0.388 | 0.452 | 0.515 | 0.642 | 0.768 | 0.895 | 1.022 | 1.149 | 1.277 | 1.404 | 1.531 |

| Mion | 0.237 | 0.298 | 0.36 | 0.421 | 0.482 | 0.605 | 0.729 | 0.852 | 0.976 | 1.098 | 1.223 | 1.345 | 1.47 | |

| s | Max | 0.438 | 0.5 | 0.562 | 0.625 | 0.75 | 0.938 | 1.125 | 1.312 | 1.5 | 1.688 | 1.875 | 2.062 | 2.25 |

| Mion | 0.425 | 0.484 | 0.544 | 0.603 | 0.725 | 0.906 | 1.088 | 1.269 | 1.45 | 1.631 | 1.812 | 1.994 | 2.175 | |

| e | Max | 0.505 | 0.577 | 0.65 | 0.722 | 0.866 | 1.083 | 1.299 | 1.516 | 1.732 | 1.949 | 2.165 | 2.382 | 2.598 |

| Mion | 0.484 | 0.552 | 0.62 | 0.687 | 0.826 | 1.033 | 1.24 | 1.447 | 1.653 | 1.859 | 2.066 | 2.273 | 2.48 | |

| k | Max | 0.188 | 0.235 | 0.268 | 0.316 | 0.364 | 0.444 | 0.524 | 0.604 | 0.7 | 0.78 | 0.876 | 0.94 | 1.036 |

| Mion | 0.15 | 0.195 | 0.226 | 0.272 | 0.302 | 0.378 | 0.455 | 0.531 | 0.591 | 0.658 | 0.749 | 0.81 | 0.902 | |

| r | Max | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.06 | 0.06 | 0.06 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| Mion | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | |

| b | L≤6 | 0.75 | 0.875 | 1 | 1.125 | 1.25 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 |

| L> 6 | 1 | 1.125 | 1.25 | 1.375 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | |

| Snàithlean sgriubha | 1-5 / 8 | 1-3 / 4 | 1-7 / 8 | 2 | 2-1 / 4 | 2-1 / 2 | 2-3 / 4 | 3 | 3-1 / 4 | 3-1 / 2 | 3-3 / 4 | 4 | |

| d | |||||||||||||

| PP | Unc | - | 5 | - | 2004/1/2 | 2004/1/2 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Unf | - | - | - | - | - | - | - | - | - | - | - | - | |

| 8-un | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |

| ds | Max | 1.658 | 1.785 | 1.912 | 2.039 | 2.305 | 2.559 | 2.827 | 3.081 | 3.335 | 3.589 | 3.858 | 4.111 |

| Mion | 1.591 | 1.716 | 1.839 | 1.964 | 2.214 | 2.461 | 2.711 | 2.961 | 3.21 | 3.461 | 3.726 | 3.975 | |

| s | Max | 2.438 | 2.625 | 2.812 | 3 | 3.375 | 3.75 | 4.125 | 4.5 | 4.875 | 5.25 | 5.625 | 6 |

| Mion | 2.356 | 2.538 | 2.719 | 2.9 | 3.262 | 3.625 | 3.988 | 4.35 | 4.712 | 5.075 | 5.437 | 5.8 | |

| e | Max | 2.815 | 3.031 | 3.248 | 3.464 | 3.897 | 4.33 | 4.763 | 5.196 | 5.629 | 6.062 | 6.495 | 6.928 |

| Mion | 2.616 | 2.893 | 3.099 | 3.306 | 3.719 | 4.133 | 4.546 | 4.959 | 5.372 | 5.786 | 6.198 | 6.612 | |

| k | Max | 1.116 | 1.196 | 1.276 | 1.388 | 1.548 | 1.708 | 1.869 | 2.06 | 2.251 | 2.38 | 2.572 | 2.764 |

| Mion | 0.978 | 1.054 | 1.13 | 1.175 | 1.327 | 1.479 | 1.632 | 1.815 | 1.936 | 2.057 | 2.241 | 2.424 | |

| r | Max | 0.09 | 0.12 | 0.12 | 0.12 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 |

| Mion | 0.03 | 0.04 | 0.04 | 0.04 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | |

| b | L≤6 | 3.5 | 3.75 | 4 | 4.25 | 4.75 | 5.25 | 5.75 | 6.25 | 6.75 | 7.25 | 7.75 | 8.25 |

| L> 6 | 3.75 | 4 | 4.25 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | |